From the Boresight Line: The Brigade Support Battalion: Providing Support to the Armored Brigade Combat Team

During previous National Training Center (NTC) rotations, the U.S. Army Training and Doctrine Command’s capability manager (TCM) for the armored brigade combat team (ABCT) observed that ABCTs are struggling with how to resupply an ABCT in the field and not from a forward operating base (FOB). Sure, fuel and ammunition get delivered, no Soldier goes hungry and health-service support takes place; however, it requires almost superhuman efforts to make it happen. At times, we are our own worst enemy and make sustainment much harder than it should be. ABCTs appear to have forgotten the mechanics of conducting sustainment operations in a field environment.

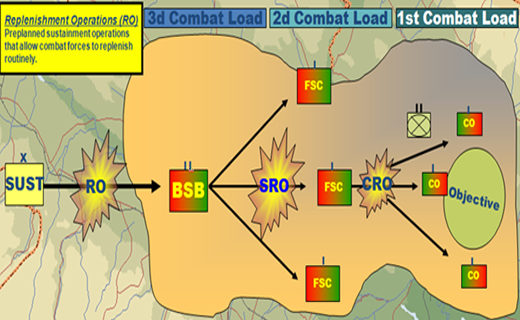

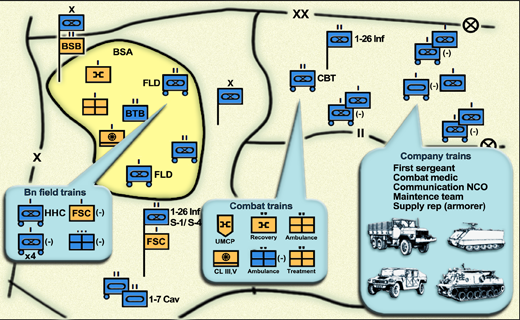

The brigade support battalion (BSB) in the ABCT is the modular organization that supports the BCT. It is organized with a supply-distribution company, maintenance company, health-services company and headquarters company. Typically, the forward-support company (FSC) is attached to each of the maneuver battalions in the ABCT (the combined-arms battalions (CAB), field-artillery battalion, Cavalry squadron and brigade engineer battalion). These companies provide the direct support to the ABCT.

How do I support my ABCT?

This is a simple answer, as the BSB provides distributive logistics and health-service support in any operational environment; on order, it redeploys and prepares for follow-on operations. The BSB provides mission command for tactical logistics and synchronizes operations among the sustainment brigade, the BSB base companies and the FSC.

Why was supporting an ABCT difficult during our last brigade field exercise? Granted, no mission failed due to a lack of supply or maintenance, and no Soldier went hungry or without rations; however, we did cut it close on more than one occasion. We were short on personnel and did not have all the enablers we should have had, but tactical logistics support should not have been this hard.

Coauthor LTC Steve Erickson quickly found that the support-operations officer (SPO) and his base company commanders were constantly in reaction mode and unable to adequately forecast or synchronize logistics across the brigade. He had a young and inexperienced staff. When he was an SPO, he knew he had to step in quickly to help get support flowing in the right direction. Unfortunately, in this case, he discovered there was not a thing he could do, as the systemic problems were interwoven with each other. The problem was not a lack of supply or failure on the part of a young staff or young commanders; it was ineffective communication among the end-user, the customer and the customer-service representative (the SPO).

What he discovered was the SPO was unable to forecast because he was not receiving logistics-status (LOGSTAT) reports that listed the supported battalion’s requirements. Not knowing what the requirements were, the SPO dispatched the distribution company to provide multi-class logistics support, but the platoon leaders on the ground (at the logistics-resupply point (LRP) or in the base-support area (BSA) would decide among themselves what needed to be provided.

“Sure, my staff may have pulled from historical documents or prediction analysis and computer models, but the brigade had been executing Red Cycle taskings for nine months and had not gone to the field as a brigade since the last NTC rotation,” Erickson recalled. “During this field exercise, we essentially got the job done through the desperate determination not to fail.”

How can the BSB support the ABCT?

Help me help you!

Logistics is a requirements-based business. Requirements drive distribution and the issue of goods and supplies. What Erickson’s BSB was missing were the requirements. “Rational people would not walk into a restaurant and just expect to be served a meal, would they? Of course not; they would order from a menu provided by the restaurant,” said Erickson. “I needed the supported (maneuver) battalions to ‘order from my menu.’ I needed them to let us know what they wanted to order off the menu with their LOGSTAT report.”

Reporting

The best way to impact any mission is for the staff to be prepared. All units in the ABCT must conduct logistics estimates and, when available, use their last-known historical data. Even with the best estimate or historical data, reporting will always be required – for nothing else than to confirm the estimate.

Reports should be based on the last 24 hours and should serve as a projection of consumption. Using the unit LOGSTAT report generated by every battalion S-4, the staff essentially reports on levels of supply that are between actual consumption and what the maximum unit capacity is. This report does two things for the supporting logistician: first, it develops a consumption history and, second, it is realistic to what the unit’s true needs are. This information also assists the logistician in determining what amounts/assets to push to the requesting unit based on asset availability and the higher commander’s priorities (similar to required supply rates and controlled supply rates).

Terminology and defining requirements

Units need to request what they require, not the manner in which they would like it to be provided. For example, units will request four fuel trucks or state they want to execute refuel-on-the-move (ROM) operations before they cross the line of departure (LD). Words have meaning; if they are used incorrectly, the mission may fail. There is a difference between a final coordination line and a final protective line, and there is a difference between a tactical refuel and ROM.

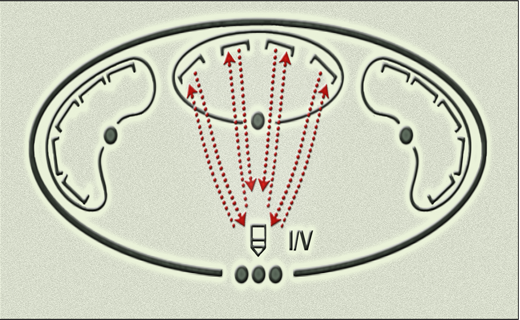

What the logistician needs to know are the facts so he/she can determine the best way to provide support while maintaining economy-of-force as it relates to logistics capacity. For example, the customer should request 6,000 gallons of fuel, and the logistician will figure out how to fulfill the request. If the operation requires any special considerations, update the operational picture thus: request 6,000 gallons of fuel, say it will be spread out among four locations and, based on the operational timeline, all four locations must be serviced at the same time.

If fuel is required just before crossing the LD, the customer does not want a ROM. A ROM is an administrative operation typically conducted in the brigade rear area of operations (AO) or in the division AO. What the customer probably wants is to have tactical fuel trucks (M978s) on line with both fuel nozzles available for a quick splash of fuel as the unit departs its assembly area. By being specific in its requirement (logistically and tactically), the supported battalion can receive exactly what it needs.

How to provide requirements in a typical ABCT

Always provide requirements via your local standard operating procedures (SOPs). Regardless of the method used, reporting will always follow this methodology:

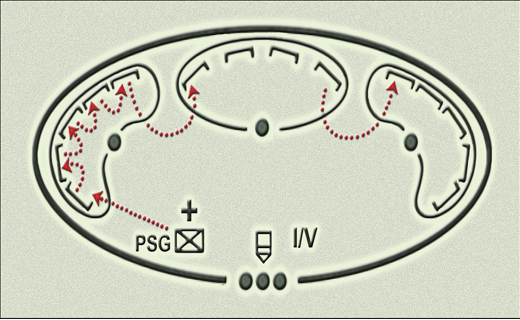

1. A platoon sergeant consolidates platoon requirements and reports to the company executive officer/first sergeant.

2. The executive officer/first sergeant consolidates the company requirements and reports to two locations: the battalion supply sergeant (S-4) and the FSC executive officer/distro-platoon leader.

3. The FSC starts consolidating requirements for its next mission and provides requirements to the BSB SPO.

4. The battalion S-4 consolidates information into a battalion logistics common operating picture (LOGCOP) and provides it to the brigade S-4. These first four steps are the responsibility of the battalion-level executive officer.

5. The BSB SPO consolidates the FSC requirements, develops the plan to support all the battalion requirements at the next brigade resupply via supply-point distribution or unit distribution (LRP operations) and requests resupply to the supporting-sustainment-brigade SPO.

6. The brigade S-4 consolidates information into a brigade LOGCOP, provides the division G-4 awareness and updates the BSB SPO on the brigade commander’s priorities for support and maintenance.

However the flow of reporting goes, constant communication between the company executive officer/first sergeant and the FSC, and communication between the FSC and the BSB SPO, are the keys to success. The secret to mission command of tactical logistics starts with knowing the requirements of supported customers. The rest is leadership and the determination of leaders on the ground to support the mission.

The FSC is the executor of the supported battalion’s sustainment plan. In layman’s terms, the FSC commander is the CAB’s SPO. The FSC needs to be part of the CAB’s military decision-making process (MDMP), and the FSC headquarters track should be co-located with the combat-trains command post (CTCP), where the CAB S-4 and S-1 reside for operations. This co-location of vehicles allows the CAB to have access to the mission-command systems in the FSC track, and the FSC to have access to the mission-command systems installed in the S-4 track.

The logistics planner (the S-4) and the executor (FSC commander or executive officer) are next door to each other. Based on the CAB SOP, the S-4 receives the LOGSTAT reports from the down-range companies, and he consolidates them into a CAB LOGSTAT for the ABCT S-4 and walks a copy to the FSC headquarters track.

Now the FSC commander can predict when and where his assets need to be on the battlefield to support the concept of the operation. Logistics are requirements-based, so the FSC commander must determine how to best support the plan based on available capabilities (enablers), limitations and restrictions. At the end of MDMP, the battalion commander must know that the FSC concept of support is doctrinally based and the plan is feasible, suitable and acceptable.

The FSC executes logistics in a distributive manner. The company is typically split into three or more locations. The combat repair teams (CRTs) are normally forward with the supported company trains; the CRT(-); FSC Rear; the FSC’s recovery section; and a refuel/rearm package at the unit-maintenance collection point (UMCP) and/or the CTCP. The FSC Rear can either be completely in the BSA with the BSB base companies or split between the BSA and operating in the battalion rear area in a task-force support area (TSFA).

Company assets from the FSC that are forward usually consist of the maintenance-control section (maintenance-control officer and technician), recovery section and portions of the line-company CRT. These are in the UMCP and are often co-located with the CTCP. The individual CRT is forward with its supported companies.

Security of the UMCP is the maintenance platoon’s responsibility using the recovery section’s M88s and other crew-served weapons.

The CRT’s forward-repair system is also located in the UMCP, and the CRT M88s are forward with the companies.

Besides the maintenance platoon, the FSC company headquarters track (M1068 currently on the modified table of organization and equipment; it is often manned by the FSC executive officer) and an on-call resupply of fuel and ammunition are located in the CTCP with the CAB S-4 track (M1068) and the battalion’s main aid station. This on-call resupply is controlled by the FSC’s executive officer but can be under the release authority of the CAB’s executive officer or S-4.

This location can become the first ambulance exchange point the evacuation platoon from “Charlie Med” uses (when coordinated through the SPO) as part of the brigade casualty-evacuation plan. The “Charlie Med” company knows to send its wheeled ambulances for casualty evacuation.

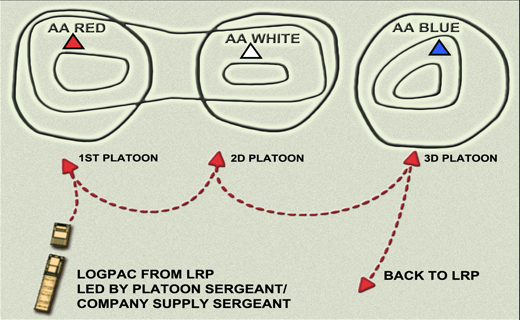

The company assets in the rear are directly tied to the BSB in the BSA. This is the case whether the rest of the FSC is completely in the BSA or split between the BSA and the TFSA. In this location, the FSC prepares and organizes the supported battalion’s sustainment and RO, commonly known as logistical packages (LOGPACs). Through LOGSTAT reports and constant communication between the FSC and the SPO, RO are either configured for the FSC to pick up using supply-point distribution (if the FSC is in the BSA), or RO are pushed (using unit distribution) via LRPs on brigade graphics for the transfer of supplies from the distribution company in the BSB to the FSC. In either case, the FSC then prepares and organizes convoy operations/march serials for LOGPAC operations.

The convoy will consist of FSC distribution assets (cargo/Load-Handling System and fuel trucks) as well as each company supply truck operated by the supply sergeant/clerk. The distribution-platoon leader or platoon sergeant leads the LOGPAC forward into the battalion area to an LRP where the company first sergeants, S-4 noncommissioned officer in charge and scout and mortar platoon sergeants are waiting to receive their LOGPAC. Each unit first sergeant or platoon sergeant will have a specified amount of time to distribute their supplies by one of, or a combination of, methods that include in-position, tailgate resupply or service-station resupply methods – then return to the LRP so the distribution platoon can return and start organizing the next RO.

Final thoughts

Remember, logistics is requirements-based. Units need to provide the actual requirements, and the logistician will fill the requirement. Do not forget that the formula for filling requirements is based on capability, assets on hand, restrictions and limitations.

Logisticians are nested with the higher commander’s plan and will follow the priority of support (restrictions). Customers should not overinflate their requirements; doing so will take away from the commander’s intent and potentially take away from the ability to complete the mission.

Units should report accurately and often, and maintain an open line of communication with their supporting unit.

email

email print

print